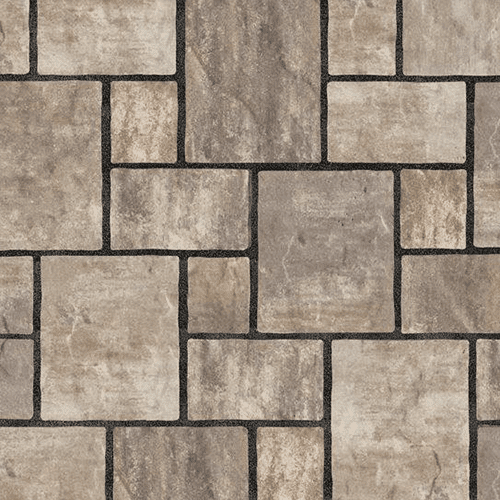

Unilock Thornbury™

Thornbury is similar to Beacon Hill Flagstone in its resemblance to natural cut stone, but is more dramatic in its surface texture and smaller in scale. A larger joint space between units adds to a more rugged look and enables water to flow through when the product is installed on a permeable base. Thornbury is a popular choice for driveways as its scale makes it capable of handling vehicular loads, and its permeability can significantly reduce puddling and ice build up in winter. Sold in a random bundle, three moderately sized units can be laid in a number of patterns for a more, or less, random appearance for virtually any application, all with the added reassurance of Enduracolor™.

Pedestrian

Permeable

Thornbury Birch

Thornbury Sierra

Brick Sizes:

Random Bundle

LARGE RECTANGLE

350mm x 420mm x 70mm

13 7/8″ x 16 5/8″ x 2 3/4″

MEDIUM RECTANGLE

210mm x 350mm x 70mm

8 3/8″ x 13 7/8″ x 2 3/4″

SMALL RECTANGLE

173mm x 210mm x 70mm

6 7/8″ x 8 3/8″ x 2 3/4″

Extra Info

Series™

The sparkling granite, quartz and feldspar crystals embedded into the surface of Series set it apart from any other paver. With our proprietary EnduraColor™ technology, these non-fading minerals will provide endless performance with a lifetime of beauty and surface resilience.

RECOMMENDED BASE STABILIZATION – one layer of DriveGrid™ stabilization grid between subgrade and base material. Recommended depth 8” to 10” below pavers for maximum stability and performance. Use under Standard Base or Permeable Base.

STANDARD BASE – Min. 6” – 8” of ¾” Crusher Run gravel (any road base standard in accordance with ASTM-D2940) compacted to 98% Standard Proctor Density (SPD).

STANDARD BEDDING COURSE – 1” thick of course sand– in accordance with ASTM-D2940) screeded over base.

ALTERNATIVE PERMEABLE BASE – Min. 6” – 8” of ¾“ clear open-graded stone compacted to achieve full particle lock-up and consolidation. (Clear open-graded does not compact but does consolidate slightly by rattling the particles together.)

ALTERNATIVE PERMEABLE BEDDING COURSE – 1” thick of 1/8” clear open-graded chip stone – (ASTM No. 8 or 9) screeded over base.

SPECIAL NOTE: CONCRETE DIRECT OVERLAY – In some areas of the country and in some applications pavers are very successfully placed directly over concrete. Concrete as a base is in itself quite strong, but it can affect the structural integrity of the paver particularly in vehicular applications, where the concrete below is sub-par. The following considerations must be taken into account to insure that the concrete below the surface is ideal:

- Concrete integrity – concrete must be in good condition, and not crumbling

- Drainage slope – concrete below must be sloped away from all buildings and structures

- Drainage holes – In lowest areas of the concrete, drill 1” holes in concrete (on 12” centers) and fill holes with ¼” chip (ASTM No. 8)

- Base drainage – the area below the concrete must not be subject to frost movement

- Surface – surface must be totally smooth and flat equivalent to the desired finished surface

- Waterproofing – may be required when installing pavers over concrete where there is a basement or cold cellar below. Install an impervious rubber membrane over the surface prior to installing any pavers over the surface.

- Jointing Sand – Use an impervious polymeric sand when installing over concrete

JOINTING MATERIAL AND JOINT STABILIZATION

All sands must meet ASTM C144 or C33 Specifications.

Good Option: Ordinary sharp jointing sand in accordance with ASTM C144 or C33. (Common name: Concrete Sand)

Best Option: Ordinary concrete sand stabilized by a water-based or solvent-based joint sand stabilizer sealer. Series has a deep texture which may trap sand particles. ALWAYS blow surface off COMPLETELY before stabilizing the sand. Refer to manufacturer’s application specifications and requirements.

HANDLING – This product has no special handling requirements.

EDGE RESTRAINT – Always install an edge restraint around the perimeter of any paver installation not restrained by building structures. Spike- in edge restraints come in plastic and various metals and work well for most applications. A concrete curb or a sub-surface concrete wedge can also be installed to retain the edge.

PAVER COMPACTION – Always use a protective polymer pad on the bottom of your compactor when doing the final compaction of the pavers. An alternative is to use a rubber roller compactor for the final compaction.

CLEANERS – Any cleaner specifically designed for pavers may be used for color restoration or general cleaning. Follow manufacturer’s dilution rates and application procedures. Always test a small area to make sure the results are as expected.

SEALERS

- Product may be sealed for aesthetic or cleanliness reasons but it is not required

- Use any sealer approved for concrete pavers

- Select type for desired aesthetics

- Product must be cleaned before sealing

- Always read and follow manufacturer’s application procedures

- Always test a small area to make sure the results are as expected